Solution

Cost-engineering helps manufacturers get an objective assessment of a product’s cost. It enables companies to reduce spending from the technical design phase to production and ultimately launch a competitively priced product.

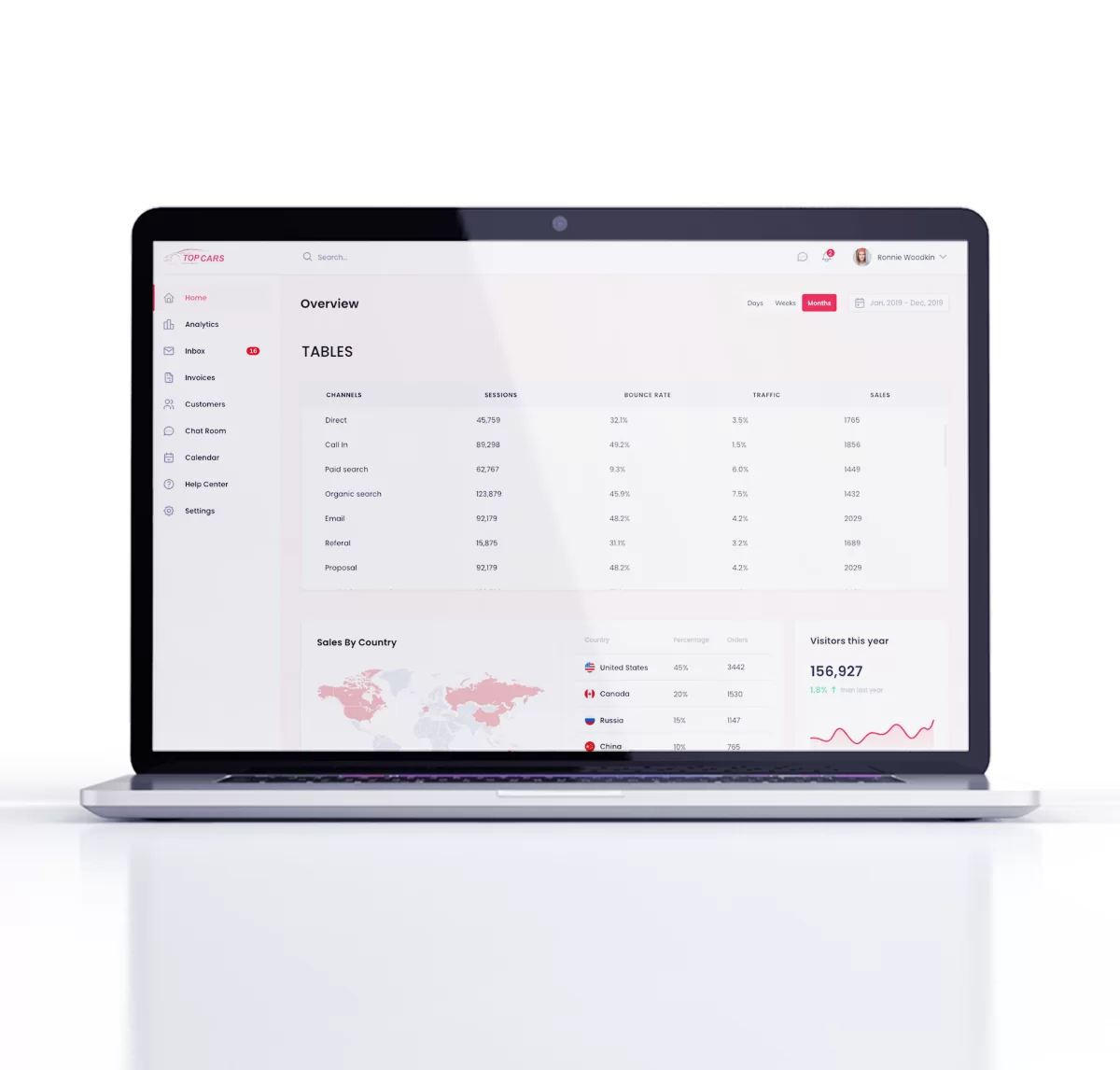

The solution our team works on is a web-based benchmarking and cost engineering platform for manufacturers in the automotive industry. Benchmarking is essential in the vehicle development process, as it provides valuable information about the competition.

The platform offers instant access to various types of information about competing vehicles, and it also allows the user, through a calculation tool, to discover country-specific costs for specific materials, logistics, etc.

The comparative data aids companies in establishing more accurate production budgets and reducing costs across components, for example, or better estimating production time.

The platform, which is used by some of the largest multinational manufacturers of vehicles from Europe and Asia, was also re-engineered and adapted for the telecom sector.

The web application and the associated database are hosted in the Azure Cloud.

Collaboration

Our client was developing a leading cost engineering platform for the automotive sector when our collaboration started.

The UK-based firm tasked our team with enhancing a platform dedicated to reducing production costs. The approach was bidirectional:

- to maintain (support, bug fixing, minor improvements) and further develop the platform with new features;

- to re-engineer and adapt it for the telecommunications industry.

Our development team took over the project from the initial crew, and after a successful collaboration, we now provide the full life cycle development of the platform using Agile methodologies.

As for the second request, the team works in an agile manner using the parts of the scrum framework that work with the fixed price project model. The solution was created for the telecommunication industry by customizing the original one based on the telecom-related requirements provided by the end client. The platform is now used by companies in Germany and the UK.

Hosted in an Azure Cloud Service, the application uses a Virtual Machine for the SQL Server instance. Fortech has both the staging and the production environment in Microsoft Azure and is using Azure Virtual Network to have them connected. The deployments are automated using a continuous integration software.