- Services

Technology Capabilities

Technology Capabilities- Product Strategy & Experience DesignDefine software-driven value chains, create purposeful interactions, and develop new segments and offerings.

- Digital Business TransformationAdvance your digital transformation journey.

- Intelligence EngineeringLeverage data and AI to transform products, operations, and outcomes.

- Software Product EngineeringCreate high-value products faster with AI-powered and human-driven engineering.

- Technology ModernizationTackle technology modernization with approaches that reduce risk and maximize impact.

- Embedded Engineering & IT/OT TransformationDevelop embedded software and hardware. Build IoT and IT/OT solutions.

- Industries

- GlobalLogic VelocityAI

- Insights

BlogsDecember 16, 2024Gene LeybzonAccelerating Digital Transformation with Structured AI Outputs

This code produces the following output that can be imported into the candidate trackin...

BlogsOctober 30, 2024Yuriy Yuzifovich

BlogsOctober 30, 2024Yuriy YuzifovichAccelerating Enterprise Value with AI

Discover how financial services integrations are transforming from standalone offerings...

- About Us

Press ReleaseGlobalLogicSeptember 23, 2025Hitachi agrees to acquire German data and AI services firm ...

Strengthening GlobalLogic’s data and consulting capabilities and expanding footprint in...

Press ReleaseGlobalLogicSeptember 10, 2025

Press ReleaseGlobalLogicSeptember 10, 2025GlobalLogic and Ericsson Deploy Private 5G Network at Hitachi ...

The new infrastructure is the digital backbone of the Hagerstown plant, enhancing effic...

- Careers

Case StudiesFlexware: Building a Culture of Product Innovation in a Service Company

Share

GlobalLogic and Method partnered with Flexware Innovation, a Hitachi Group Company, to assist with market research and development of LIFT 3.0 intralogistics software, the first standalone product that Flexware has developed. This collaboration aimed to enhance its user experience, efficiency, reliability, and market fit.

Challenges

Flexware Innovation, now part of the Hitachi Group, is an industrial engineering and integration firm. Two years ago, they embarked on a significant initiative to develop LIFT 3.0, their new intralogistics software.

As this was their first experience of stand-alone product development, Flexware’s core problem was understanding their new product’s market fit. They wanted to define their target customers, identify their pain points, understand how LIFT 3.0 would integrate into existing technical ecosystems, and assess their willingness to buy. Furthermore, they needed to compare LIFT 3.0 to competitive solutions and determine effective go-to-market strategies.

To address these challenges and ensure a successful go-to-market strategy, Flexware sought external expertise in modern product design.

What is LIFT 3.0 by Flexware Innovation?

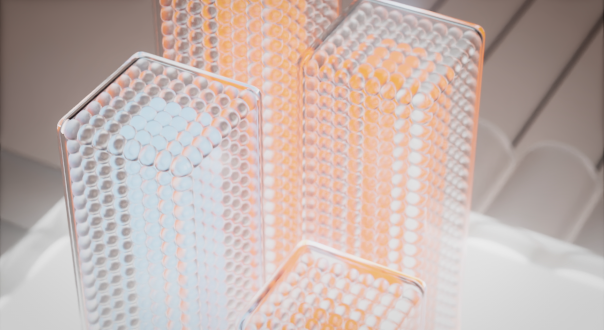

This intelligent material movement software is designed to connect and orchestrate automated vehicles and enterprise systems (like ERP) in manufacturing and warehousing operations. It aims to eliminate silos, reduce manual work, and optimize material flow.

LIFT 3.0 addresses the lack of communication between disparate systems with robust integration capabilities, drag-and-drop workflow automation, and real-time monitoring and alerts, increasing connection and efficiency.

Value Created

Method guided Flexware through a structured 12-week process to identify, test, and validate opportunity hypotheses, leveraging decades of experience in consulting on digital strategy, experience design, and modern product development.

This systematic approach, formalized by Method based on their prior innovation program collaboration with Hitachi’s innovation teams, resulted in the creation of an “innovation playbook”. This playbook serves as a repeatable framework for understanding and validating ideas and defining a go-to-market approach.

GlobalLogic significantly contributed to the LIFT product by developing and implementing a robust quality assurance strategy and enhancing the LIFT 3.0 UX/UI. We boosted the platform’s value by optimizing front-end performance and streamlining QA processes. GlobalLogic’s engineering team’s UI development led to an improved user experience. Through a blend of manual and automated testing, we increased the platform’s reliability, ensuring consistent performance and minimizing errors.

Working with GlobalLogic and Method provided the clarity and reassurance we needed to refine our LIFT product strategy and go-to-market approach. Their structured innovation process not only validated our direction but also equipped our team with lasting capabilities to successfully launch and position our solution in the market.Brice Bucher VP of Products Flexware InnovationImpact

GlobalLogic’s collaboration with Flexware significantly advanced the stability and performance of LIFT 3.0. By enhancing the platform’s front-end and streamlining QA processes, the engagement resulted in an improved user experience and a more reliable, efficient platform. Our partnership with Flexware not only improved their product’s reliability and user experience, but it also helped Flexware optimize the cost of software development and accelerate their time to market.

Beyond the technical enhancements, the partnership’s biggest impact was providing Flexware with a crucial “gut check” and realignment on how to define their go-to-market approach. Our collaborative approach focused on not just delivering an outcome but also on teaching Flexware to improve their innovation capabilities. This included providing a product playbook to help Flexware’s team members understand how to operate effectively as a product team and replicate the innovation process internally. This playbook was seen as a valuable resource for onboarding team members and improving their effectiveness in the innovation cycle, empowering Flexware for long-term success in further digital product developments.

LIFT by Flexware Innovation optimizes manufacturing and warehousing material movement by integrating automated vehicles with existing ERP systems, eliminating data silos, minimizing manual labor, and streamlining material flow.

Our partnership with Flexware not only improved their product’s reliability and user experience, but it also helped Flexware optimize the cost of software development and accelerate their time to market.

Featured insights

Explore fresh thinking from GlobalLogic’s strategists and engineers.

See allBlogs30 October 2025Revolutionizing Data Centers with AI and Digital Twins

GenAIIT/OT TransformationTransformation AdvisoryTransformation Execution and GovernanceIndustrial and EnergyTechnology Blogs29 October 2025

Blogs29 October 2025How GenAI is Powering Manufacturing’s Pragmatic Revolution

How GenAI is Powering Manufacturing’s Pragmatic Revolution

GenAIIT/OT TransformationTransformation Execution and GovernanceIndustrial and Energy Case StudiesGlobalLogic

Case StudiesGlobalLogicHitachi Aqua-Tech Engineering Leverages GlobalLogic’s Digital Expertise …

Facing limitations of their legacy architecture, Hitachi Aqua-Tech Engineering …

Industrial and Energy Get in touch

Get in touchLet’s start engineering impact together.

GlobalLogic provides unique experience and expertise at the intersection of data, design, and engineering.

Loading...

How can I help you?

How can I help you?

Hi there — how can I assist you today?

Explore our services, industries, career opportunities, and more.

Powered by Gemini. GenAI responses may be inaccurate—please verify. By using this chat, you agree to GlobalLogic's Terms of Service and Privacy Policy.